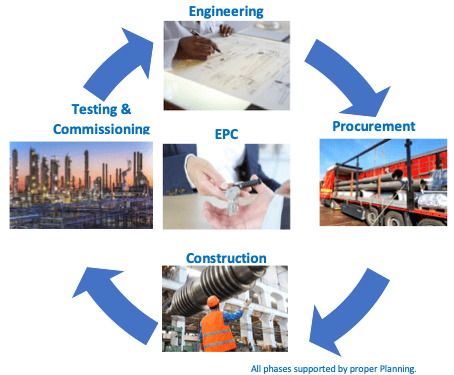

Engineering, Procurement and Construction (EPC) is one of the most important methods of managing large industrial and infrastructure projects. This method includes three main stages of Engineering, Procurement and Construction, which are carried out in an integrated and coordinated manner.

EPC Definition

EPC is a comprehensive method for managing large projects that includes design, procurement of equipment and materials, and construction and installation of the project. This method allows the employer to entrust all stages of the project to a single contractor and benefit from better coordination and reduced risks associated with the project.

EPC Stages

Engineering: In this stage, detailed design and planning of the project is carried out, which includes the preparation of drawings, technical specifications and engineering calculations. The aim of this stage is to ensure that all technical aspects of the project are properly defined and documented.

Procurement: In this stage, the equipment and materials required for the implementation of the project are procured, which includes the selection and purchase of equipment, materials and services from reliable suppliers. The aim of this stage is to ensure the timely and quality supply of equipment and materials.

Construction: In this stage, the construction and installation of the project is carried out, which includes the execution of construction works, installation of equipment and commissioning of systems. The purpose of this stage is to ensure the correct and timely execution of the project.

Benefits of EPC

Better coordination: By entrusting all stages of the project to a single contractor, coordination between different stages of the project is improved and delays and problems caused by inconsistencies are avoided.

Risk reduction: The EPC contractor is responsible for all stages of the project, which reduces the risks associated with the project for the employer.

Cost control: Using the EPC method, project costs are controlled more accurately and unexpected cost increases are prevented.

Challenges of EPC

Management complexity: Managing EPC projects requires high management experience and skills due to the breadth and complexity of the various stages.

Supply risks: Supplying equipment and materials from different suppliers may face risks such as delayed delivery or poor quality.

Need for careful coordination: Coordination between different stages of the project and ensuring the correct execution of each stage requires careful planning and continuous monitoring.

EPC Applications

The EPC method is used in large industrial and infrastructure projects such as power plants, refineries, oil and gas transmission lines, and large construction projects. This method allows the employer to implement complex and large projects with high efficiency and productivity.

Conclusion

In the end, the EPC method is one of the most important and efficient methods of managing large projects, using which projects can be implemented in an integrated and coordinated manner. Considering the advantages and challenges of this method, the use of EPC requires high management experience and skills. Training and updating knowledge in the field of EPC is essential for all project managers and engineers.

The International Group of Mehr Pars Plateau, with a focus on; planning and use of tools and machinery and the expertise and capabilities of managers, experts and personnel in future project plans, intends to play an important role in the PC of the project.